Curved structures

Tulppa panels can be used to easily create unique, curved structures for the bathroom. Included below are instructions for constructing a curved shower wall.

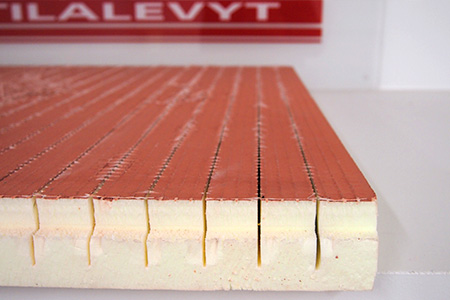

1. When you know the desired radius, use the following formula to calculate the distance between the required grooves: radius = thickness of the panel x distance between grooves / width of groove, which means that the distance between grooves = radius x (width of groove / thickness of groove). (Note! The formula is indicative.) The panels can be grooved horizontally or vertically.

Mark your sawing lines according to the results from the formula. (Note! Distance is measured from edge of groove to edge of groove.)

2. Saw grooves into the panels using a portable circular saw or table saw.

3. The grooves have to be deep enough to leave approximately 15–20 mm of the thickness remaining. This ensures that the panel is sturdy enough to bend without breaking.

4. Saw evenly spaced grooves into the board across the section you wish to curve. You can also saw the grooves closer to each other in areas you want the panel to curve with a tighter radius.

5. After cutting the grooves, bend the panel such that the edges of the grooves touch each other.

Cut off an appropriately sized piece of fiberglass mesh and attach it to the internal surface of the curved panel with mortar. The panel must retain the intended curve until the mortar has dried. Easiest way to ensure this is to use tie down straps.