Installation instructions for a sheet metal element wall

You should never place two waterproofing layers on top of each other. Use spacers measuring 6 x 100 mm made from Finnfoam (XPS insulation) to ensure proper ventilation for sheet metal element walls. The tiling of an existing sheet metal element wall is cleaned with denatured alcohol or another similar cleaning agent.

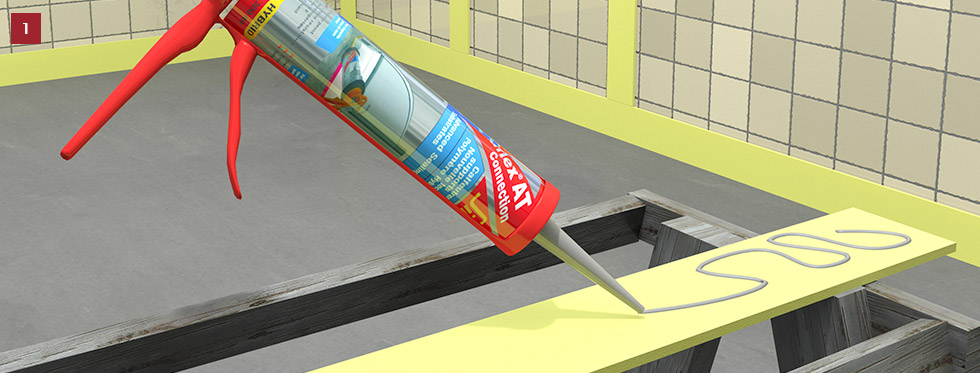

Next, the spacers are attached to the wall using an adhesive compound from the chosen product range. The Finnfoam spacers are laid vertically as a skeleton with an on-center spacing of 600 mm (K600) and against the floor for “downstream”. If you want to use horizontal spacers above the floor level, it is necessary to include vertical ventilation gaps. The reason for this is that the ventilation gap behind the Tulppa panels is ventilated into the ceiling space, i.e. above the dropped ceiling.

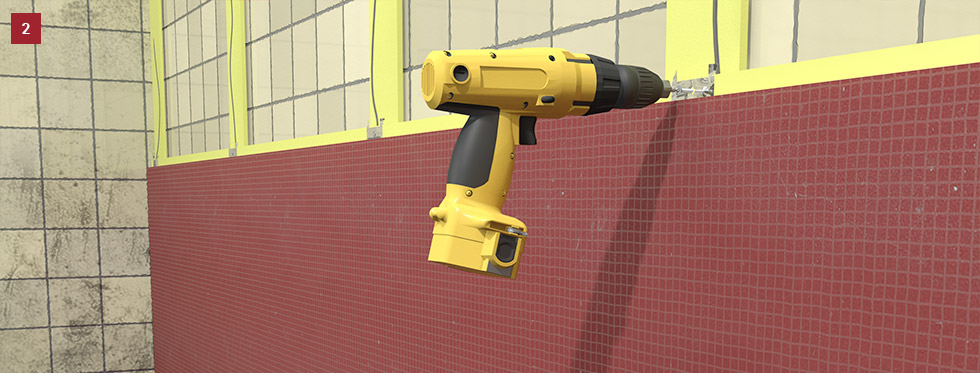

Drill a few holes into the lower section of the existing wall between each line of spacers to ensure ventilation. If the ventilation gap can be ventilated into a ceiling space which is ventilated further, two holes with a diameter of 10 mm will suffice at the lower section of each space between studding. If ventilation is not possible, two holes with a diameter of 10 mm must be drilled into each studding space every 400–500 mm.

The Tulppa panels are attached to the spacers using an adhesive compound from the chosen product range such that the joints between panels are placed on top of the spacers. In addition, the panels are secured using Tulppa O brackets (also at the intersection of the floor and the wall) on top of the spacers using self-drilling screws. The joints between the panels, passages, and the gap between the floor and the wall are sealed similarly to beam frames.

Perform the sealing and waterproofing in accordance with the rabbeted Tulppa wet room panel installation instructions for timber or metal frames.